The following article was originally published by Emobility Engineering magazine, published April 11, 2024 Read …

Axial Flux Versus Radial Flux

Yokeless axial flux and radial flux permanent magnet machines have a lot in common. In fact, from an electromagnetic perspective, they are almost identical. Both work on the same electromagnetic principles, and both have copper windings, iron cores, and permanent magnets.

Therefore, it’s quite remarkable how some rather subtle differences in topology turn out to have a huge compounding effect on the torque density and efficiency of the machine.

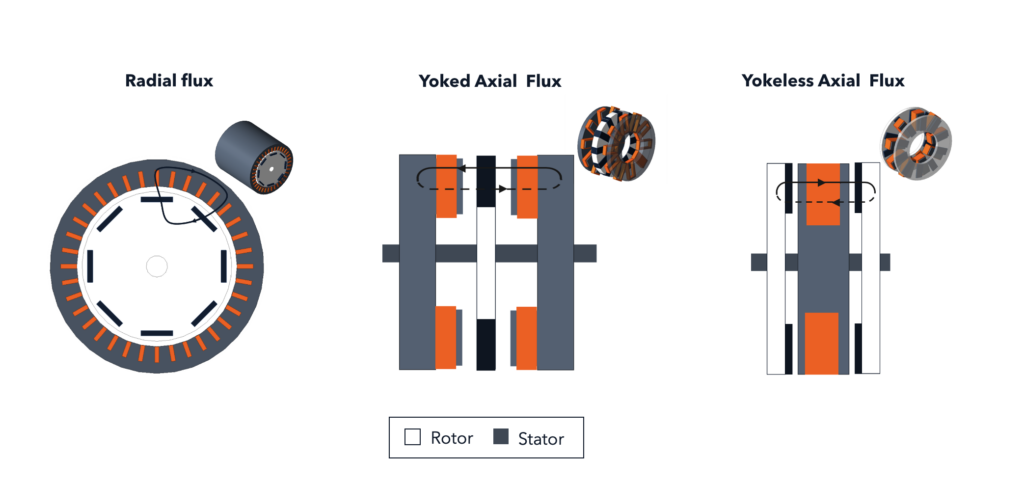

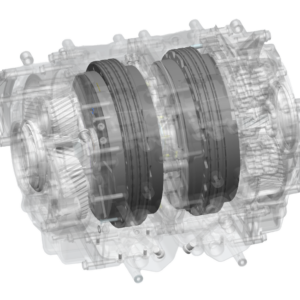

Almost all electric motors used today, both in a mobility context and beyond, have the radial flux topology. This topology consists of a cylindrical rotor that spins inside a cylindrical stator, depicted in Figure 1. In this system, the electromagnetic flux, which is the source of the torque in the machine, first circulates radially outward from the rotor to the stator, then circumferentially along the stator from one stator tooth to the next, returns radially inward from the stator to the rotor, and finally closes the flux loop along a tangential path in the rotor.

A different approach is to place a single rotor disk between two lateral stators, or two rotor disks on either side of one central stator, also depicted in Figure 1. The single-rotor dual-stator topology is also called the ‘yoked axial flux’ type, while the dual-rotor single-stator topology is called the ‘yokeless axial flux’ type.

Most of the advantages of yokeless axial flux machines over radial flux machines fundamentally originate from the inherently higher utilization rate of copper, electrical steel, and magnets.

Yoked axial flux machines also offer some of these advantages, but crucially, not the most impactful ones.

Therefore, we’ll further limit the scope of this paper to the yokeless axial flux machines.

The following post is the first in a 4-part series based on a paper presented at the 2023 CTI Symposium in Berlin by Traxial cofounder Peter Leijnen.

See part 2 here: The Theory: Fundamental Advantages Delivering Substantial Performance Improvements in Axial Flux Motors

Part 3: The Practice: Resolving the Challenges [COMING FEB 20]

Part 4: Yokeless Axial Flux Topology as the Driver for Future Powertrains [COMING FEB 27]

Get the technical data sheet of our latest axial flux motor, the AXF300-85s

This Post Has 0 Comments