The following article was originally published by Emobility Engineering magazine, published April 11, 2024 Read …

Axial Flux Motors: Revolutionizing Electric Vehicles for a Greener Future

As the electric vehicle growth continues unabated, the rising fuel prices due to supply chain disruptions and political tensions will continue to incentivize consumers to consider more fuel-efficient battery electric vehicles (BEV’s) and hybrid electric vehicles (HEV’s) further accelerating their adoption.

In addition, stringent emissions regulations and government incentives for electric vehicle adoption will push automakers to explore alternative motor technologies to meet efficiency and environmental targets. Axial flux motors, with their potential for higher efficiency & sustainability, will become more attractive in this regulatory landscape.

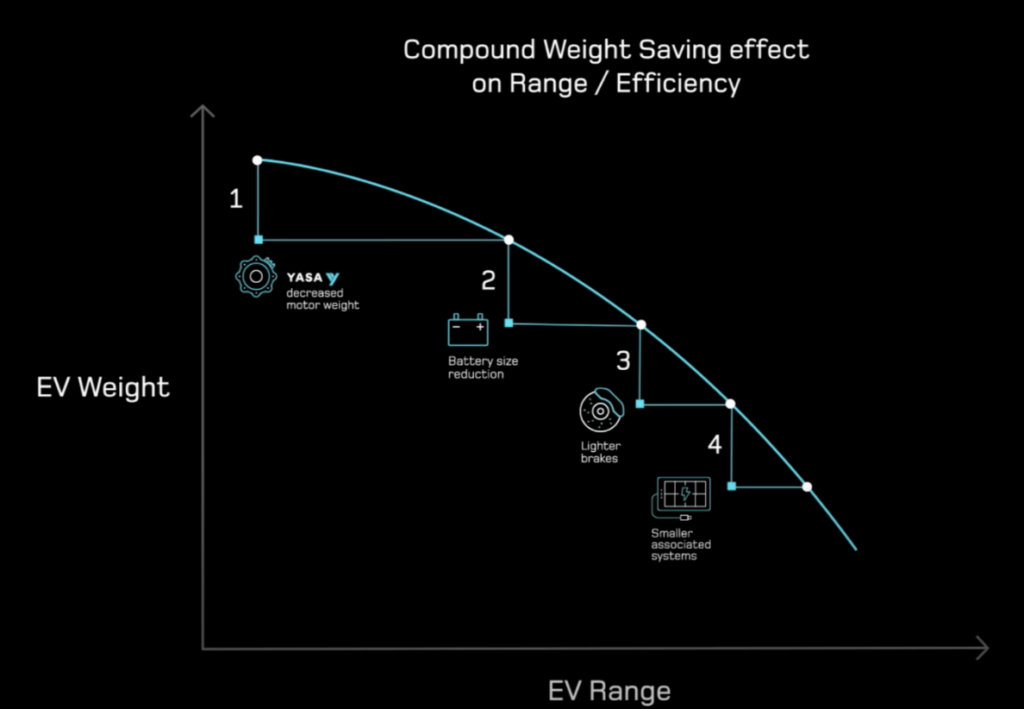

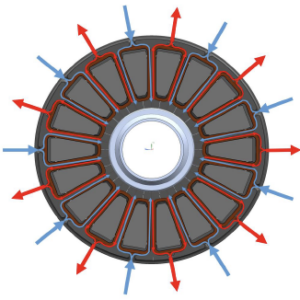

Axial flux motors present numerous advantages in terms of compactness compared to traditional radial flux motors, including high torque and power density and the ability to reduce total weight, particularly in the powertrain. This gained space and weight advantage not only enhances the performance of electric vehicles but also contributes to extending their range naturally. Ultimately, this leads to the development of more sustainable and efficient solutions in the realm of electric vehicles.

That’s not the only way you can reach more sustainable solutions with axial flux. Due to reduction of copper and using less material in the motor for the same required unit torque and power, axial flux motors provide more sustainable and efficient powertrain solutions.

Latest studies show that up to 50% environmental load unit (ELU) reduction and up to 65% toxicity reduction is possible with axial flux motors compared to equivalent radial flux motor applications. Also, from the product life cycle perspective up to 50% CO2 reduction is possible with axial flux motors.

Note: One ELU represents an externality corresponding to one Euro environmental damage cost.

In 2024, at the Davos Economic Forum, one of the 4 key topics was a long-term strategy for climate, nature and energy. Most probably this is only one of the signs that sustainability and efficiency would be a highly focused topic for future electric vehicles or hybrid powertrains. Axial flux application advantages will help automotive manufacturers to meet the targets from this perspective and answer market and government need in the coming years.

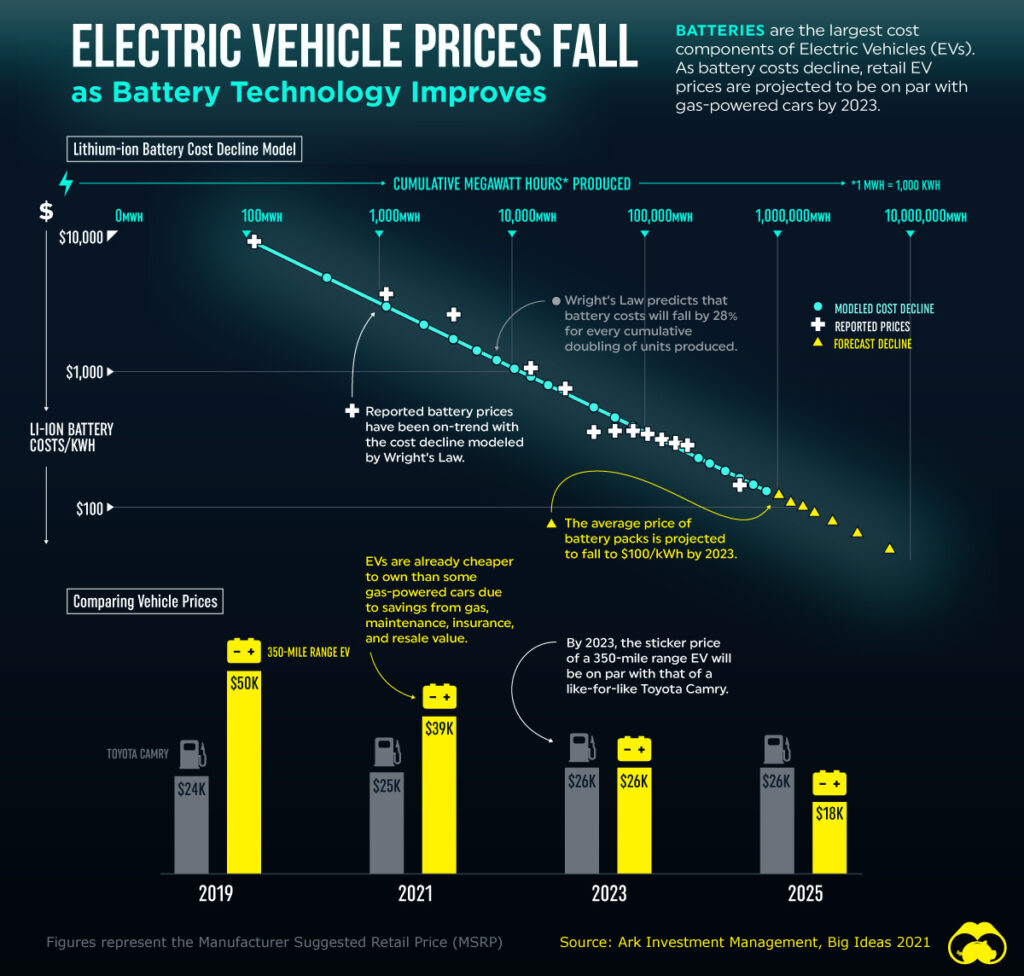

The world stands at the cusp of a significant transition. By 2025, the cost of producing electric vehicles (EV’s) is projected to undercut that of conventional cars, spurring a more rapid adoption of EV’s. Moreover, it’s anticipated that supply chain costs for EV’s will subsequently plummet. Axial flux motors are poised to play a pivotal role in this shift. It’s highly probable that by the end of the decade, we’ll witness a substantial decrease in the production costs of axial flux motors, further increasing their market-share.

Another dramatic advantageous effect of axial flux motors can be for in-wheel applications. The small size and high torque output of axial flux motors will lead to their growing use in in-wheel applications. Using axial flux motors per wheel will also have an effect in decreasing the serial production cost of an axial flux motor.

Considering all the items mentioned above, it is not a surprise that almost 90% of major OEM’s are working on axial flux applications either by acquisitions or by internal developments, which is supported by recent patent applications. Axial flux motors will have a significant role in the ground transportation and automotive landscape over the future years and decades.

Overall, while radial flux motors currently dominate the electric vehicle market, this technology will soon be superseded because of the advantages that axial flux motor technology provides for all high-voltage battery electric and hybrid electric vehicles.

References:

Bhutada, G. (2022, April 30). Electric Vehicle Prices Fall as Battery Technology Improves. Visual Capitalist. https://www.visualcapitalist.com/electric-vehicle-battery-prices-fall/

YASA Limited. (2023, June 12). The YASA Story – Axial Flux Motors: The Future of Electric Vehicle Propulsion [Video]. YouTube. https://www.youtube.com/watch?v=3qjB6G

This Post Has 0 Comments